Antique Washbeton

Washbeton is a kind of floor covering which it’s surface is made of high-grade aggregate and is used for landscaping of the villa, garden, walkway, car parking, pool surround, and industrial areas.

Antique Washbeton Code : WW5020

واش بتن آنتیک سالار کد WW5020

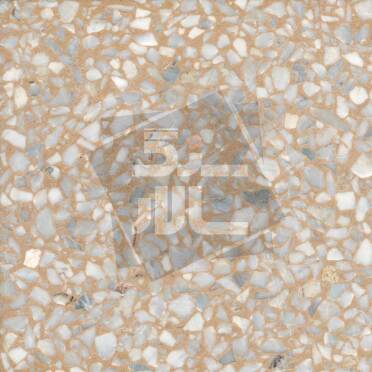

Antique Washbeton Code : WY5040

واش بتن آنتیک سالار کد WY5040

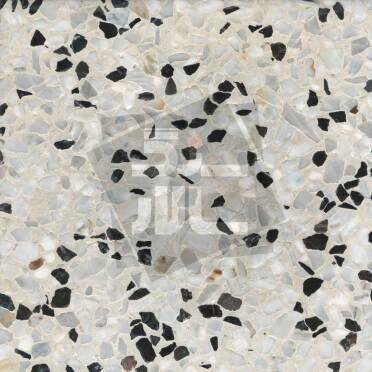

Antique Washbeton Code : WY6040

واش بتن آنتیک سالار کد WY6040

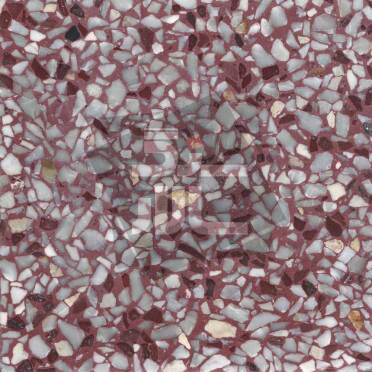

Antique Washbeton Code : WW5020B

واش بتن آنتیک سالار کد WW5020B

Antique Washbeton Code : WW7020

واش بتن آنتیک سالار کد WW7020

Antique Washbeton Code : WW6030

واش بتن آنتیک سالار کد WW6030

Antique Washbeton Code : WW4050B

واش بتن آنتیک سالار کد WW4050B

Antique Washbeton Code : WW6020

واش بتن آنتیک سالار کد WW6020

Antique Washbeton Code : WK8020

واش بتن آنتیک سالار کد WK8020

Antique Washbeton Code : WW3010

واش بتن آنتیک سالار کد WW3010

Antique Washbeton Code : WK9050

واش بتن آنتیک سالار کد WK9050

Antique Washbeton Code : WWBC1166

واش بتن آنتیک سالار کد WWBC1166

Types of Washbeton:

Washbeton (monolithic): In the past, when the mosaic production machinery was not built yet, people were using exposed aggregate concrete.

After preparing the desired space, the concrete mixture was prepared and disposed in the mold, flat the surface then washed with water pressure, cement around the aggregates were washed and part of the surface of the stone was highlighted. This model was not suitable due to the lack of accurate formulation, the impossibility of pressing and vibration and ultimately improper curing of concrete, and after a short time lost its quality and aggregates separated from the surface of concrete. There for, this kind of flooring cover was inaccessible for construction and to architects and civil engineers.

Vibrating Washbeton:

Due to the problems with the implementation of washed aggregate , the technology of vibrating Washbeton was made and a lot of manufacturing workshops were launched for the production of vibrated washed concrete.

For producing the vibrating Washbeton, we pour the mixture of concrete, stone powder, and aggregates and water into the rubber molds in dimensions 30*30, 40*40, and 30*60 and placed on the vibration table. The reason for placing on the vibration table is the discharge of bubbles of the concrete, which will increase the density of washed concrete and reduce the amount of water absorption , after 24 hours of the relative strength of washed concrete, they will be take out from the mold and by water washing, the surface of it will be exposed.

Despite the fact that this method is better than the washed aggregate, but unfortunately due to the incomplete vibration system, resistance and quality are not acceptable for employers, contractors and consultant engineers.

Pressed Washbeton:

After the dissatisfaction of engineers, employers and construction contractors and consulting engineers with the quality and technical characteristics of vibrated Washbeton, the technology of making pressed Washbeton, was formed. In production of pressed washed concrete, the process of producing was more completed.

In this method, the raw materials including cement, aggregate, stone powder and water mixed into the mold, to fill 50 % of the mold, then the remaining mold capacity with the cement and sand with very little water filled and pressed.

The action of the press causes the extra water of the front layer to be added to the back of it.

Pressure strength should be at least 300 Tones. After pressing remove the Washbeton and put it in the steam room for 24 hours and then wash the surface. The quality of this type of Washbeton is much better than the vibrated types.

The dimensions of this type of Washbeton are 30*30, 40*40 &50*50.

Unfortunately, many units use small pressed machines about 25 to 50 tones, which cause the Washbeton has low density and has a high water absorption that make them vulnerable to cold and frost.

On the other hand, except for one or two large units in the country, the other units have not a steam room, which causes to cure badly and do not have good molecular consistency and is not resistant to traffic. Formulation of raw material is another factor, unfortunately many of units have not equipped in laboratory and this factor affecting the quality of pressed Washbeton.

Antique Washbeton:

Antique Washbeton is a new generation of Washbeton in the world. This is produced by a very advanced and equipped machinery that is exclusively owned by Breton (Italy). In the process of this type of Washbeton, the selection of raw materials, including aggregates, micronized powder, cement, water, colored pigments and concrete additives, is initiated with special sensitivity.

The aggregates should be accordance with the relevant standards in compression strength, water absorption, abrasion coefficient and cement resistance.

Micronized powder, cement, color pigments and concrete additives should be standard.

The water used in the mixing should be refined and free of mineral salts.

The used of specialized carboxylate super-lubricants in mixing, reduces the amount of water to cement in concrete, which results in addition to high-density, the absorbing water will reduce and increases the flexural strength.

Sazan Sang Salar

NO.57 , KOUROSH ST. , NORTH SOHREVARDI , TEHRAN.IRAN

88500500 21 98 +

41154 21 98 +

a 2023©All Rights Reserved